Celtec High Temperature PEM Fuel Cell MEA (25cm2)

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Celtec High Temperature PEM Fuel Cell MEA (25cm2)

FCS

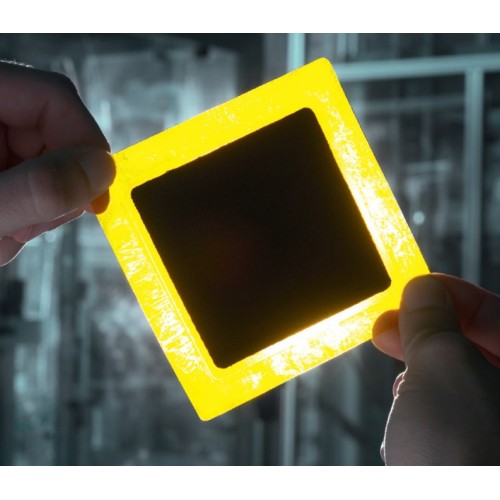

Celtec®-P Membrane Electrode Assemblies:_x000D_ _x000D_ BASF offers a membrane electrode assembly (MEA) for high-temperature proton exchange membrane (HT-PEM) fuel cells and other relevant applications. This MEA operates at temperatures between 120 and 180 °C and can tolerate large concentrations of carbon monoxide as well as being able to run independently of humidification. This technology enables fuel cell systems to become simpler and more cost effective._x000D_ _x000D_ This Celtec®-P MEA has and active area of 25cm2 (5 by 5 cm) and it comes with the proprietary anode and cathode electrodes that are already bonded to the membrane. A PDF drawing of the MEA design is given below. _x000D_ _x000D_ MEA Design:_x000D_ _x000D_ Fuel Cell Store currently offers the following standard MEA designs:_x000D_ _x000D_ Celtec®-P MEA 25 cm2_x000D_ _x000D_ Celtec®-P MEA 45 cm2_x000D_ _x000D_ Celtec®-P MEA 165 cm2_x000D_ _x000D_ _x000D_ _x000D_ _x000D_ For any other tailored or customized high temperature proton exchange membrane fuel cell (HT-PEMFC) MEAs

please contact us atsales@fuelcellstore.com._x000D_ _x000D_ Applications and Properties of Celtec®-P MEAs:_x000D_ _x000D_ Some of the applications that can benefit from BASF Celtec®-P high temperature proton exchange membrane fuel cell MEAs are provided below. Some of the major properties of these MEAs are also provided in the table below._x000D_ _x000D_ Applications_x000D_ Properties_x000D_ _x000D_ Backup Power_x000D_ _x000D_ Combined heat

power

and cooling_x000D_ _x000D_ Auxiliary power units_x000D_ _x000D_ Battery range extender_x000D_ _x000D_ _x000D_ Based on polybenzimidazole and phosphoric acid_x000D_ _x000D_ Operating temperature 120 to 180 °C_x000D_ _x000D_ High tolerance to carbon monoxide in the fuel mixture_x000D_ _x000D_ No humidification is necessary_x000D_ _x000D_ Long operational lifetime and stability (>20k hours)_x000D_ _x000D_ _x000D_ _x000D_ _x000D_ _x000D_ _x000D_ _x000D_ Fuel Cell Performance of Celtec®-P MEAs:_x000D_ _x000D_ Hydrogen/Air and Reformate/Air reactant based fuel cell performance of Celtec®-P MEAs are provided below. _x000D_ _x000D_ _x000D_ _x000D_ _x000D_ CO Tolerance of Celtec®-P MEAs:_x000D_ _x000D_ One of the major benefit of the high temperature proton exchange membrane fuel cell technology is the capability of consuming the reformed hydrogen stream

it is essential that MEAs used in such electrochemical devices have excellent carbon monoxide tolerance. During the reformation reaction

there is a small amount of the carbon monoxide gas generated in the fuel stream exiting the reforming catalyst bed

and presence of carbon monoxide can impact the overall fuel cell performance. BASF Celtec®-P MEAs uses a proprietary anode and cathode catalysts in order to allow the Celtec®-P MEAs tolerate high levels of carbon monoxide compared to the other commercial high temperature PEMFC MEAs. The following graph provides an example performance curve for Celtec®-P MEAs at different CO concentrations as a function of temperature. _x000D_ _x000D_ _x000D_ _x000D_ _x000D_ _x000D_ Robust Performance Against Humidity Changes for Celtec®-P MEAs:_x000D_ _x000D_ Conventional high temperature PEMFC devices would usually use a polybenzimidazole PBI) or a co-polymer of PBI membrane that is phosphoric acid doped after the production of the membrane. Such membrane activation and containment of the liquid acid inside the membrane result in acid leaching phenomenon. PEM fuel cells generate water as the main by-product at the cathode side and presence of water further impacts the acid leaching phenomenon with the conventional PBI membrane. Celtec®-P MEAs utilized an advance form of PBI membrane where the proprietary tetraamino monomer and dicarboxylic acid monomer are first reacted via polycondensation reaction in phosphoric acid and then a solution casting & hydrolysis step is carried out in order to obtain the Celtec®-P membrane. This sol-gel synthesis protocol allows the PBI membrane to attain a novel morphology where the phosphoric acid is contained inside the membrane more effectively and has less acid leaching issues compared to conventional PBI membranes. Laboratory test results showed that operational lifetimes of exceeding 20

000 hours can easily be achieved with Celtec®-P MEAs and Celtec®-P membranes. The following graph provides the robust performance of Celtec®-P MEA against different humidity conditions._x000D_ _x000D_ _x000D_ _x000D_ _x000D_ For customers that purchased this product

a copy BASF Fuel Cell Handbook will be provided separately (free-of-charge) in an electronic format such as PDF file._x000D_ _x000D_ Celtec-P MEA Design Technical Data Sheet for 25cm2 Active Area _x000D_ _x000D_ A typical lead time of 1-2 weeks is to be expected.