MTI | SKU:

HC12SiN

Max. 550C Heating Jacket and Temperature Controller with 12mm ID Si3N4 Pressing Die - EQ-HC-SiN-12

Regular price

€267.206,00

Unit price

/

Unavailable

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

Max. 550C Heating Jacket and Temperature Controller with 12mm ID Si3N4 Pressing Die - EQ-HC-SiN-12

MTI

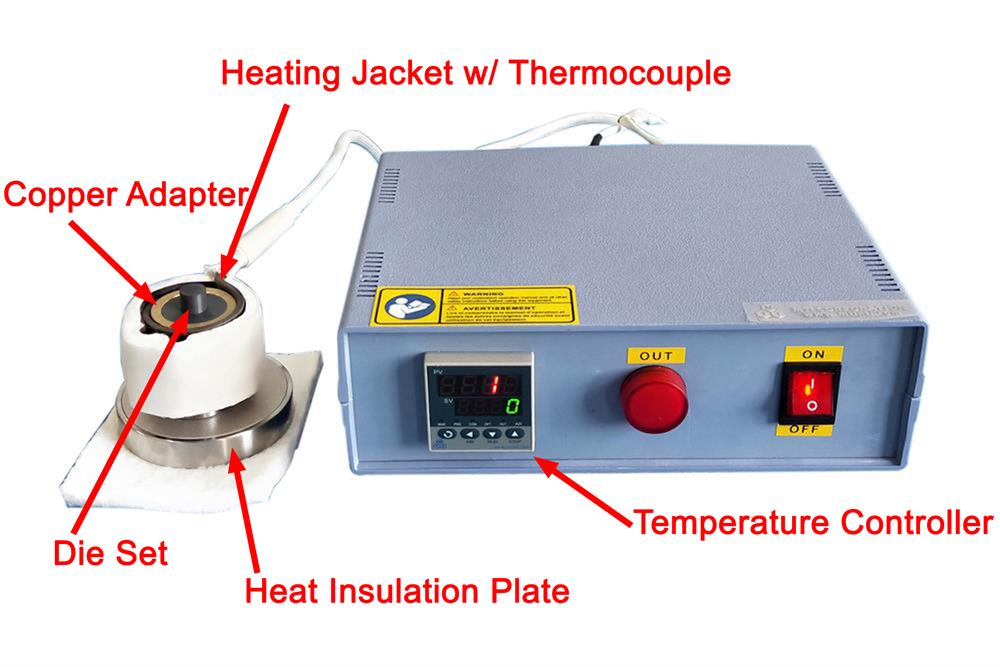

EQ-HC-SiN is designed for heating 12mm I.D. Silicon Nitride Pellet Pressing Die with Heating jacket (550°C Max.) and Temperature Controller. Programmable Temperature Controller is standard from 03/09/2021.

SPECIFICATIONS:

| Model | HC12SiN | HC20SiN |

Structure  |

The 12mm SiN Heatable Die Set includes:

|

The 20mm SiN Heatable Die Set includes:

|

| Voltage |

|

|

| Power |

|

|

| Working Temperature and Pressure |

|

|

Temp. control method |

|

|

| Instruction Video |

|

|

| Application Note |

|

|