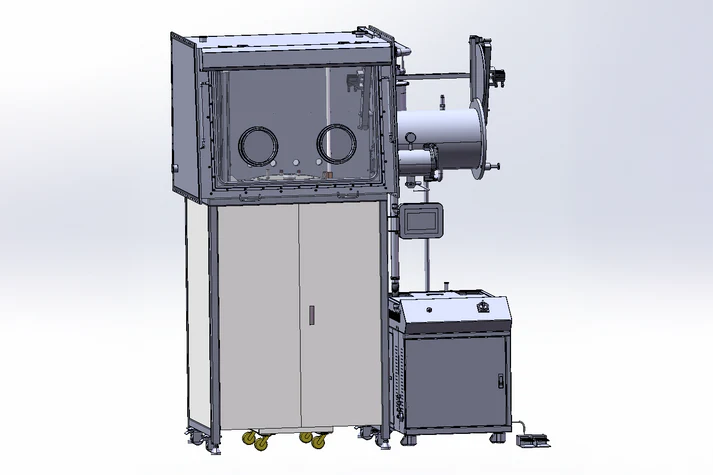

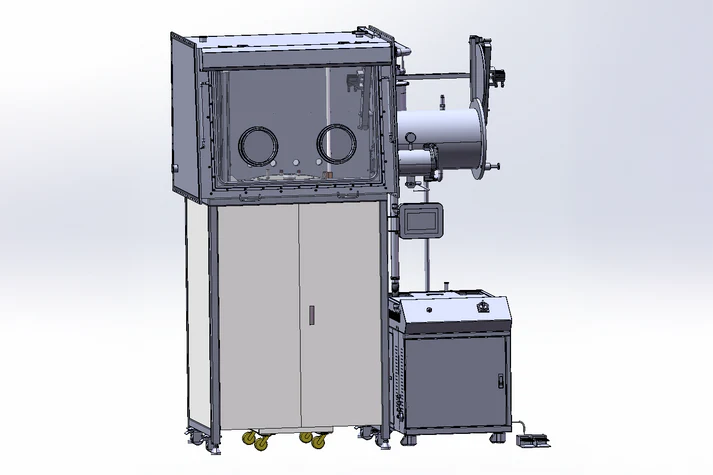

1100°C High Pressure ( 1.2 MPa) Liquid Phase Epitaxy Crystal Growth Furnace & Glove Box System - HP1100X-LPEGB

Couldn't load pickup availability

Delivery and Shipping to EU

Delivery and Shipping to EU

We will add in the quotation, the shipping, insurance, customs clearance costs.

1100°C High Pressure ( 1.2 MPa) Liquid Phase Epitaxy Crystal Growth Furnace & Glove Box System - HP1100X-LPEGB

MTI

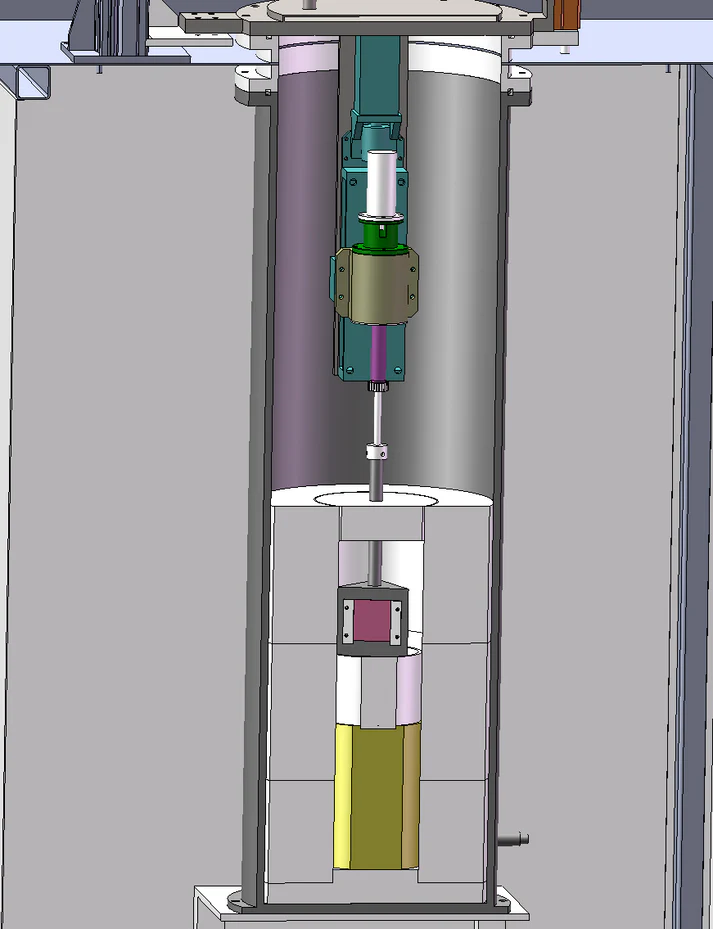

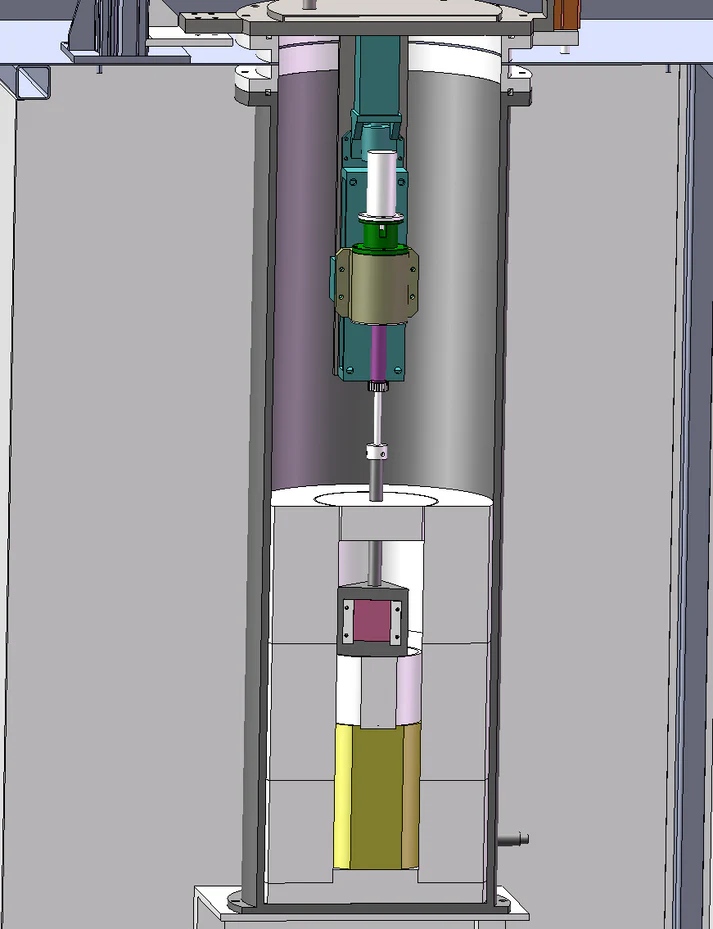

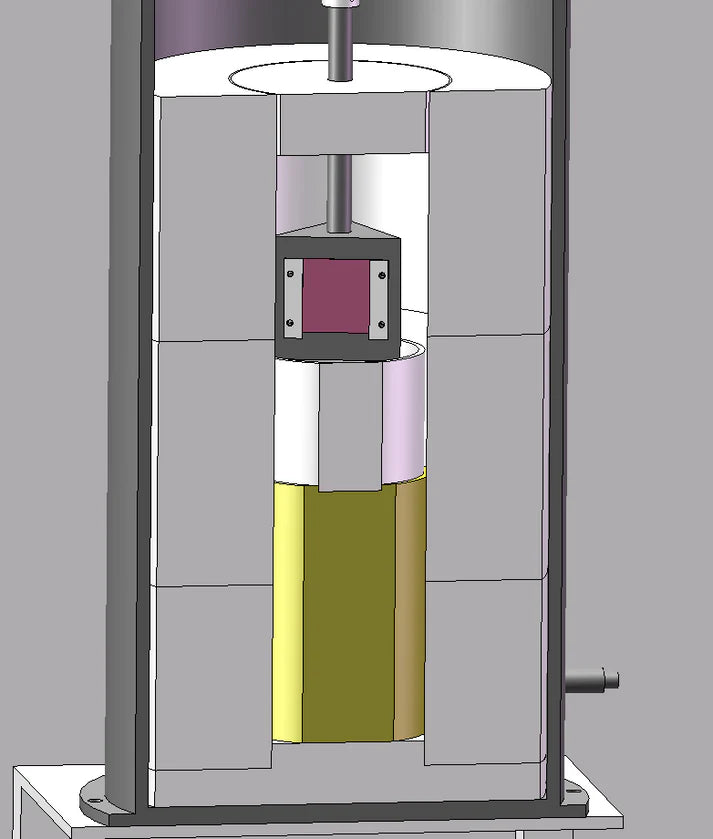

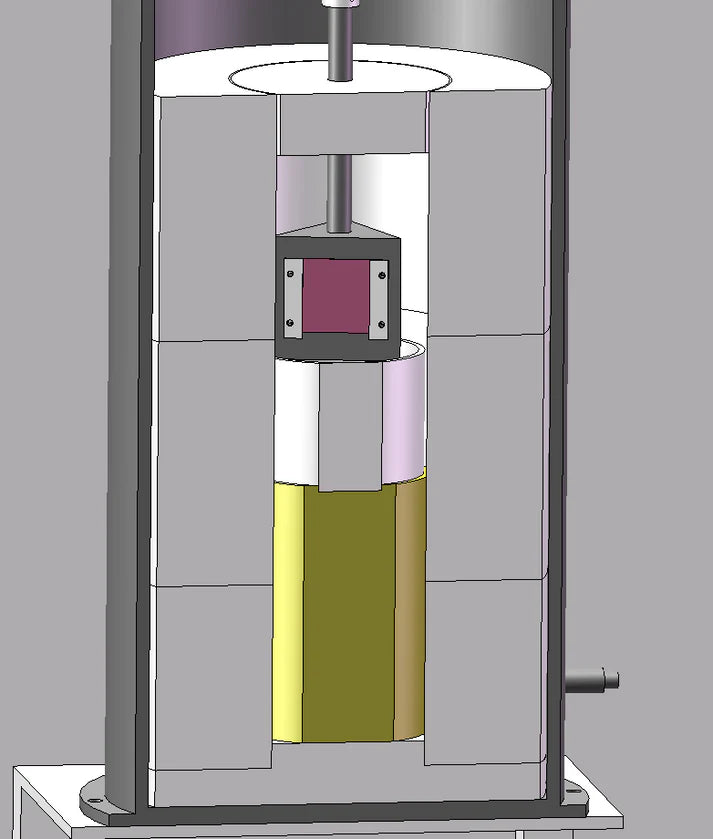

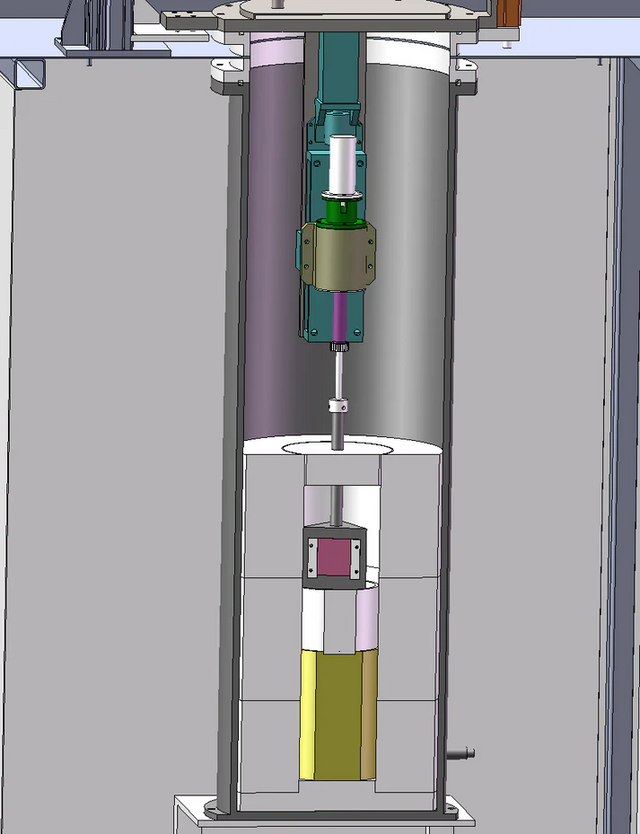

HP1100X-LPEGB combines a liquid phase epitaxy crystal growth furnace with a glove box system, enabling the installation and removal of liquid phase epitaxy crystal growth accessories under inert atmosphere protection. It can also achieve liquid phase epitaxial growth under high pressure conditions, with a maximum pressure of 1.2MPa (at 700°C). It is an ideal equipment for liquid phase epitaxial growth of HgCdTe (MCT) and other thin films.

Specifications

|

Structure |

|

|

Power |

|

|

Heating Element |

|

|

Working Temperature |

|

|

Heating Zone |

|

|

Production |

|

|

High Pressure Chamber |

|

|

Glove Box System |

|

|

Temperature and Pressure Control System |

|

|

Vacuum System |

|

|

Dimension |

|

|

Weight |

|

|

Application Note |

|