MTI | SKU:

RTP-MS-AR

2500°C Max. High Vacuum & Ultrafast Heating Pellet Press with Automated 8 Samples Loading System - RTP-MS-AR

Prezzo normale

€0,00

Prezzo unitario

/

Non disponibile

Non è stato possibile caricare la disponibilità per il ritiro

Consegna e spedizione nell'UE

Consegna e spedizione nell'UE

Nel preventivo aggiungeremo i costi di spedizione, assicurazione e sdoganamento.

2500°C Max. High Vacuum & Ultrafast Heating Pellet Press with Automated 8 Samples Loading System - RTP-MS-AR

MTI

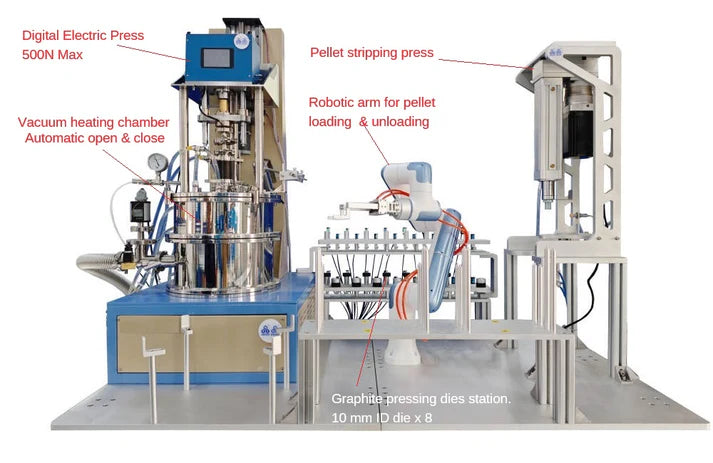

- RTP-MS-AR is an automatic Ultrafast Heating and Pressing system (UHP) with a heating speed of up to 150°C/s, 2500°C, and 500N Max Load inside a high vacuum chamber made of stainless steel. The automated pellet loading and unloading system is integrated into the press, which can press 8 pellets ( 10 mm ID) per batch. This system may be considered as an automatic SPS furnace

Features

- Stainless steel high vacuum chamber up to 5x10-5 torr ( Cold state) with automatic open & close function

- Flash sintering up to 150°C/s and 2500 °C

- Pressure for sample pressing up to 500N

- Infrared pyrometer for temperature control

- Fully automated operation via a robotic arm to press 8 pellets per batch within 6 hours

SPECIFICATIONS:

|

Power

|

|

|

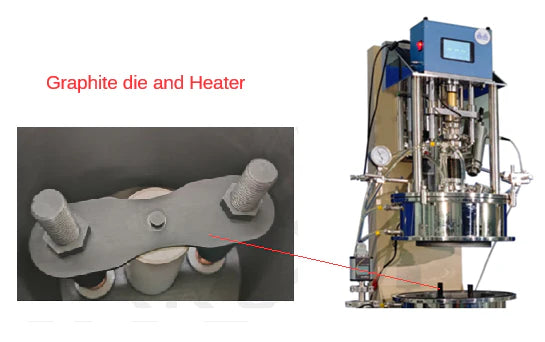

Graphite die & Heater

|

|

|

Temperature Control

|

|

|

Vacuum Pump (Optional)

|

|

|

Water Chiller (Optional)

|

|

|

Standard Operating Procedure ( SOP) |

|

|

Compliance

|

|

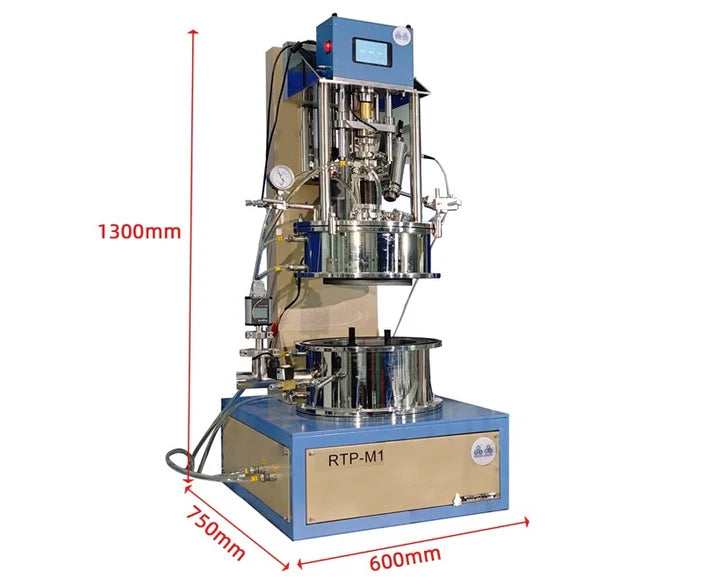

Dimension

- Main Body: 1100mm(L)*750mm(W)*1900mm(H)

Weight:

- Main Body: 300kg

MTI offers a One-Year limited warranty for this product.

The MTI One Year Limited Warranty does NOT cover

- Consumable parts, such as graphite dies, O-rings, crucibles, screws, washers, glassware, etc.

- Any damage and rust resulting from improper storage or maintenance.

- Any damages caused by the use of corrosive and acidic gases.

- Any damage resulting from failing to adhere to the individual product's specific operation requirements, such as water cooling, venting, etc.