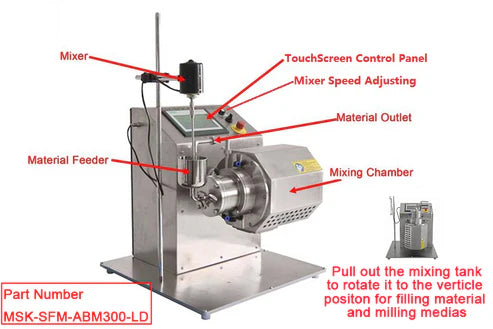

| Part Number |

MSK-SFM-ABM300-LD |

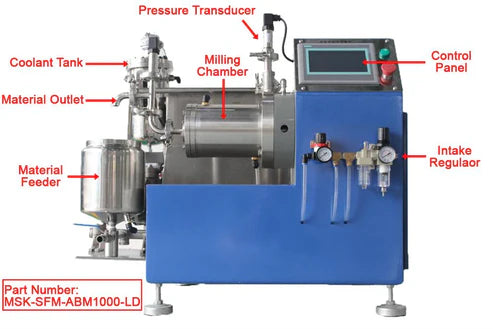

MSK-SFM-ABM1000-LD |

| Features |

- Highly efficient milling system that combines bead milling and centrifugal separation

- Wear and corrosion-resistant design for metal-free processing with a milling chamber and rotor made of ceramic

- Self-circulation with a closed system for circulation and multi-pass milling operation

- High-purity zirconia milling balls are included for immediate use

|

- Our large-capacity milling system offers outstanding efficiency compared with earlier models.

- Highly efficient milling system that combines bead milling and centrifugal separation

- Wear and corrosion-resistant design for metal-free processing with a milling chamber and rotor made of ceramic

- Self-circulation with a closed system for circulation and multi-pass milling operation

- High-purity zirconia milling balls are included for immediate use.

-

|

| Input Power |

- 208 - 240 VAC, 50 Hz, single phase.

- 110VAC version is available via 1500W transformer

- 1.1 kW power

|

- 208-240 VAC, 50/60 Hz

- 4 kW power

- 208-240V, 3 phase, 50/60Hz is available upon request

|

| Milling Operations |

- Motor speed: 600 - 2880 rpm programmable

- Milling chamber capacity: 300 mL

- Milling chamber material: Zirconia

- Milling rotor design: Peg grinding system with a small length/diameter ratio

- Milling rotor material: Zirconia

- Milling media size: 0.3 - 1.4 mm

- 0.7 kg 0.3-0.4 mm high purity milling media is included, which fills up to 70% of the chamber

|

- Motor speed: 2850 rpm

- Milling chamber capacity: 1000 mL

- Milling chamber material: Silicon carbide

- Milling rotor design: Peg grinding system with small length/diameter ratio

- Milling rotor material: Zirconia

- Milling media size: 0.3 - 1.4 mm

- Slurry viscosity: 1-100,000 cps

|

Milling Media

|

- 0.7 kg 0.3 mm diameter YSZ mill ball is included for immediate use,

- Other sizes of YSZ mill ball is available upon request.

- Usually, the Milling ball vs Material is 7:3, and a small output particle requires a smaller milling ball.

- Warning: Max. the mill ball size is 1.4 mm (A larger ball may damage the mill chamber). It is the customer's responsibility to find the best parameter for your own sample by experiment.

|

- Other sizes of YSZ mill ball is available upon request.

- Usually, the Milling ball vs Material is 7:3, and a small output particle requires a smaller milling ball.

- Warning: Max. the mill ball size is 1.4 mm (A larger ball may damage the mill chamber). It is the customer's responsibility to find the best parameter for your own sample by experiment.

|

| Self Circulation |

- Self-circulation with a closed system for circulation and multi-pass milling operation

- Separation filter net material: Tungsten Steel

- Separation filter net pore size: <0.3 mm

|

- Self-circulation with a closed system for circulation and multi-pass milling operation

- Separation filter net material: 304 stainless steel

- Separation filter net pore size: 0.12 mm

|

| Cooling |

|

|

| Application Notes |

- Always use the equipment on a level & stable surface for the best performance and maximum safety

- If the liquid is spilled on the unit, first disconnect the unit from external power and then clean the unit with a cloth

- The equipment is NOT intended to use for dry milling of powders!

- To avoid powder clumps and achieve the best milling results, 1) sieve the powder prior to milling, 2) mix milling media of different sizes, and do the milling

|